- Reception of registration and entry photo

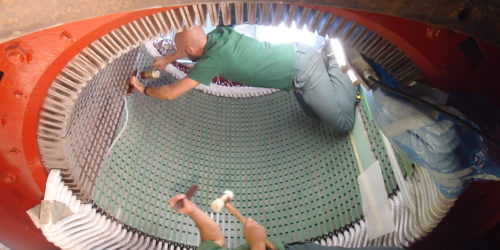

- Dismantling

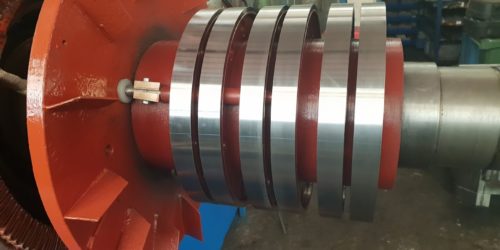

- Checking of bearing seats, shafts, flanges, etc.

- Washing

- Drying in oven

- Mechanical and electrical metrology according to standards and report

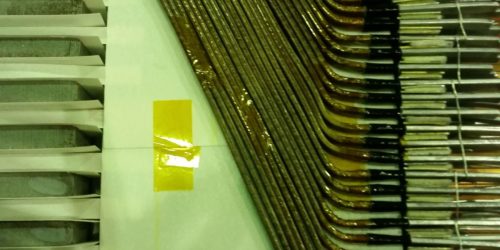

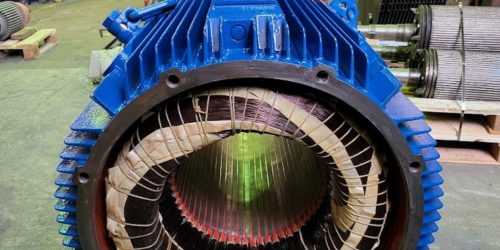

- Maintenance and/or rewinding

- Anti-flash protective varnish

- Replacement of bearings

- Complete mechanical and electrical checks

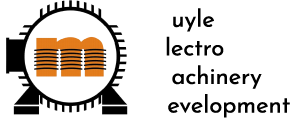

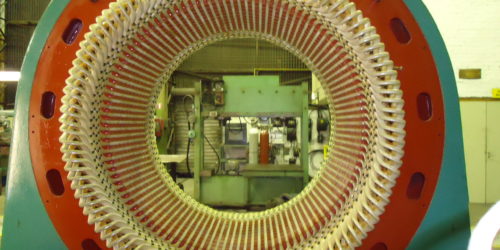

- Mechanical work: banding, reloading, grinding of manifolds, milling of micas, etc.

- No-load rotation tests

- Report

Workshop

Maintenance and repair

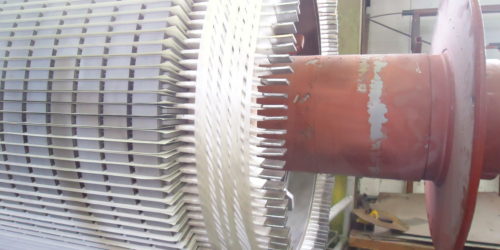

Balancing

- Static and dynamic balancing on calibrated Schenck balancing machine

- Max capacity : 4.5 T

- Max. diameter: between bearings 1.6 m and outside bearings 2.8 m

- Length between bearings: 2.5 m

- With report and certificate

- Static and dynamic balancing on calibrated … balancing machine

- Max capacity : 5T

- Max. diameter : between bearings 1.6 m outside

- Length between bearings : 3.6 m

- With report and certificate

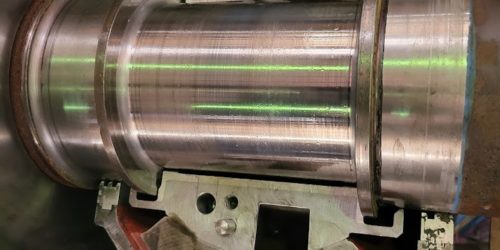

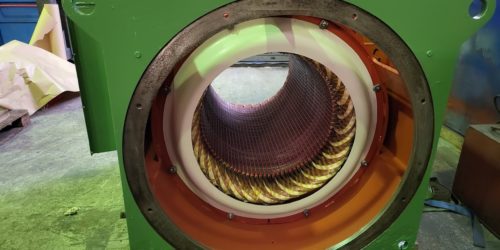

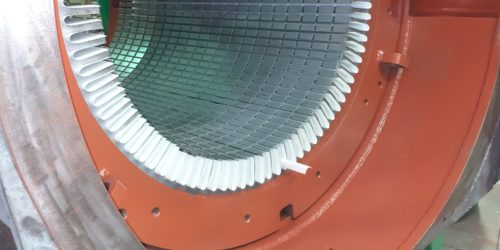

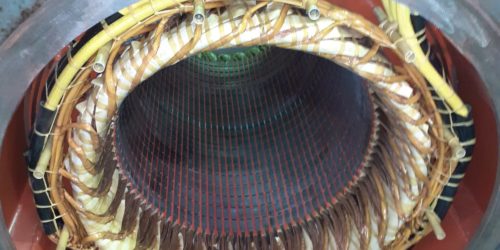

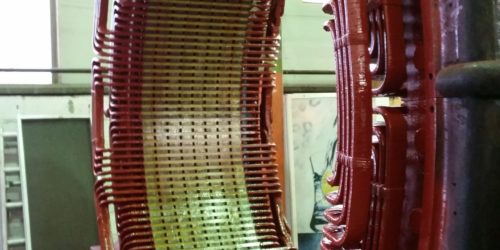

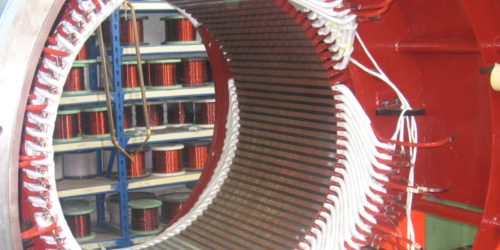

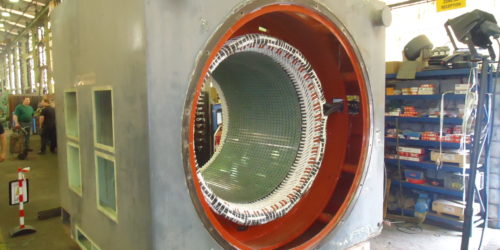

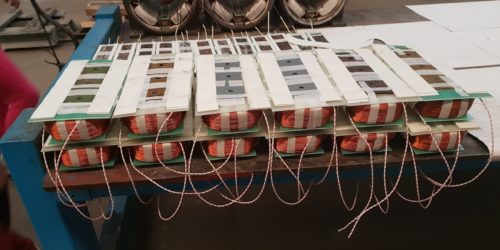

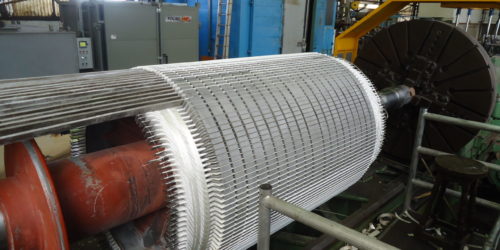

Winding

- Asynchronous motor with cage for all powers up to 30 tons LV&HV

- Slip ring motor

- DC motor

- Schrage motor,

- Special parts, chokes, coils, brake, etc….

- In round wire as well as in flat wire

- Submersible pump

- Vacuum and pressure impregnation, class H

- Polymerization in oven

- Transformer

- Alternator

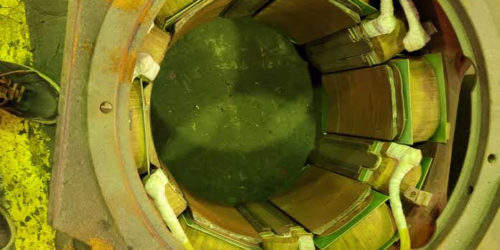

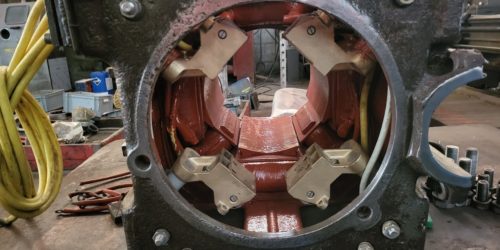

Traction motor

Reloading

Test bench equipment

Machining and boiler making

Production of all parts according to drawings and/or models

Overviews

MEMD carries out refurbishments of traction motors from spare parts, among others for traction motors.

By carrying out these repairs, we give the motor a new life, it is reconditioned like new.

This makes it possible to put mechanical and/or electrical installations back into operation.

Inspections

- Major engine inspection

- Endoscopic inspections

- Electrical test

- Major inspection in case of engine failure

- Delta tangent measurements in the workshop and on site.

- Some examples of the latest delta tangent tests performed